3M Press Release

Published October 11, 2010

3M GETS THE CALL TO DELIVER ENHANCED BONDING FOR TELEPHONE MANUFACTURER

An innovative combination of industrial tapes and adhesives from diversified technology company 3M is helping to deliver greater durability and product life for a leading specialist manufacturer of commercial telephones.

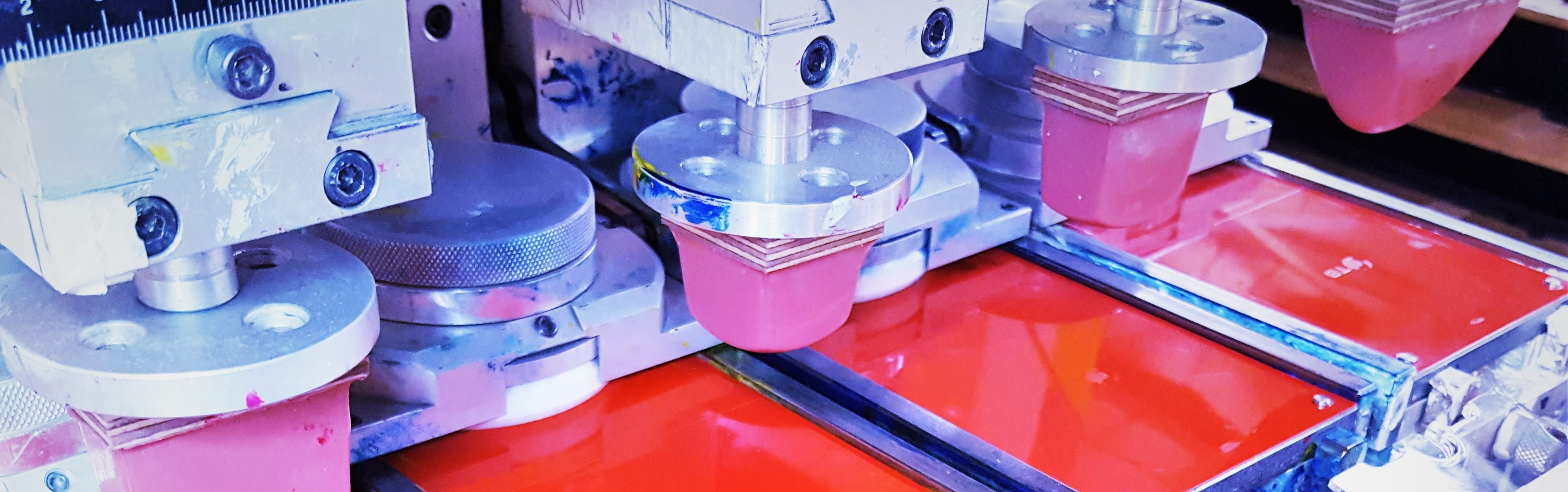

RS Coatings Ltd manufactures the enclosure sets for sophisticated communications interface devices. The enclosure sets – (around 300 each day) – are supplied to an electronic service manufacturer which installs all the internal components. The finish product is then supplied to a major telecommunications provider for sale primarily to stock exchanges and brokers worldwide.

RS Coatings designed a range of die cut forms around the product lay-out. This more user friendly bonding method, increased the contact surface area between windows and front covers, maximizing this adhesive’s performance. With this philosophy in mind and in order to maximize adhesion between components, a further bonding upgrade was suggested by 3M, coupling the die-cut tape with 3M Scotch-Weld Acrylic Adhesive DP807. This is a two-part MMA acrylic-based adhesive which reaches handling strength in 15 minutes, with high overlap shear and peel strength offering excellent durability on most plastic surfaces.

The combination of these two adhesive products has delivered excellent results with zero failures in-service.

RS Coatings Ltd Managing Director Laurie Richardson commented: “3M’s response to the reported problem was prompt and very professional, offering alternative solutions and product samples imminently. Overall the bonding system now in place more than meets expectations. The die cut tape enables a quicker and easier application while reducing waste, and the use of an adhesive in tandem with the tape is creating a far stronger bond.”

“Currently the products are being applied manually, but we are looking at automating the adhesive application process.”

Rob Musgrove of 3M’s Industrial Adhesives & Tapes Division added: “This application shows the versatility of 3M products and how they can work together to create the perfect bonding solution – whether applied manually or automatically.”

Further information on the Scotch-Weld range of tapes and adhesives can be found at www.3M.co.uk/Scotchweld. For details on other 3M Industrial Adhesives & Tapes products, visit www.3M.co.uk/adhesives.

3M is a trademark of 3M Company.

3M – practical and ingenious solutions that help our customers succeed

3M is a $23 billion diversified technology company which, since 1902, has been creating innovative products that help make the world healthier, safer and more productive. Well known 3M brands include Scotch, Post-it, Scotchgard, Thinsulate and Scotch-Brite.

3M employs some 75,000 people worldwide and has operations in more than 60 countries. It produces tens of thousands of innovative products for customers in dozens of diverse markets and its 45 technology platforms touch nearly every aspect of modern life. The company has applied its expertise in RFID (radio frequency identification) technology to map and locate underground utilities; it has used its understanding of the healthcare industry to develop innovations that help the early diagnosis of heart and lung conditions; and its range of pocket projectors are the ultimate presentation devices for business people on the go.

The UK and Ireland is home to one of the largest 3M subsidiaries outside the USA, employing more than 3,500 people across 17 locations, including 10 manufacturing sites.

Products manufactured in the UK include coated abrasives, occupational health and environmental safety equipment, adhesive tapes, industrial microbiology products, drug delivery systems, high-performance coatings, secure documents and passport scanners.

3M Centre, Cain Road, Bracknell, Berkshire, RG12 8HT

Tel: 08705 360036

www.3M.co.uk/adhesives