The dynamic industrial environment and changing markets worldwide have challenged the manufacturing sector in theUK. RS Coatings have succeeded to adapt and compete with major international players by offering a comprehensive finishing service and by incorporating new technologies and innovative techniques within their operations.

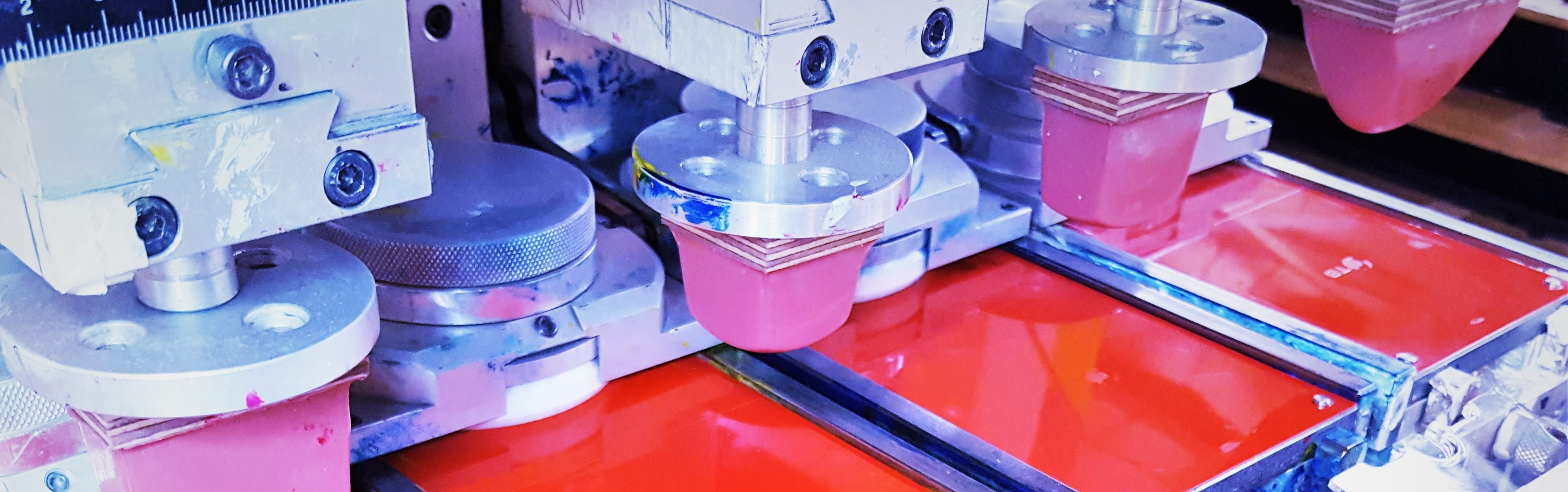

RS Coatings’ experienced and well prepared technical crew holds wide engineering knowledge in Coatings and Application Techniques, Polymers, Tooling, Design and Automation. The combination of these has recently enabled the in-house design, development and commission of a purpose built automated plant for the application of scratch resistance UV cured lacquers.

The plant is totally sealed with an anti-static curtain integrated within the loading base, minimising air-born contamination. The goods are automatically conveyed through the various stations. The operations are activated and de-activated in sequence, as the product is conveyed. The multi-station plant includes a binary and automatic application of the lacquer, IR and UV curing stations and product recognition.

“The system was originally designed for the application of scratch-resistance lacquers to British Telecom components. The moulding and decorating of the BT Netrix display-lenses already takes place here at RS Coatings inCannock. It only seemed natural to develop the process in-house and apply an additional process to this product rather than out-sourcing and complicating the manufacturing logistics involved.” Declares Laurie Richardson, Managing Director of RS Coatings.