Secondary Operations

Below is a list of some of our Secondary Operations:

PLASTIC INJECTION MOULDING

-

Machine range up to 240 TON.

-

All polymers are moulded including engineering plastics

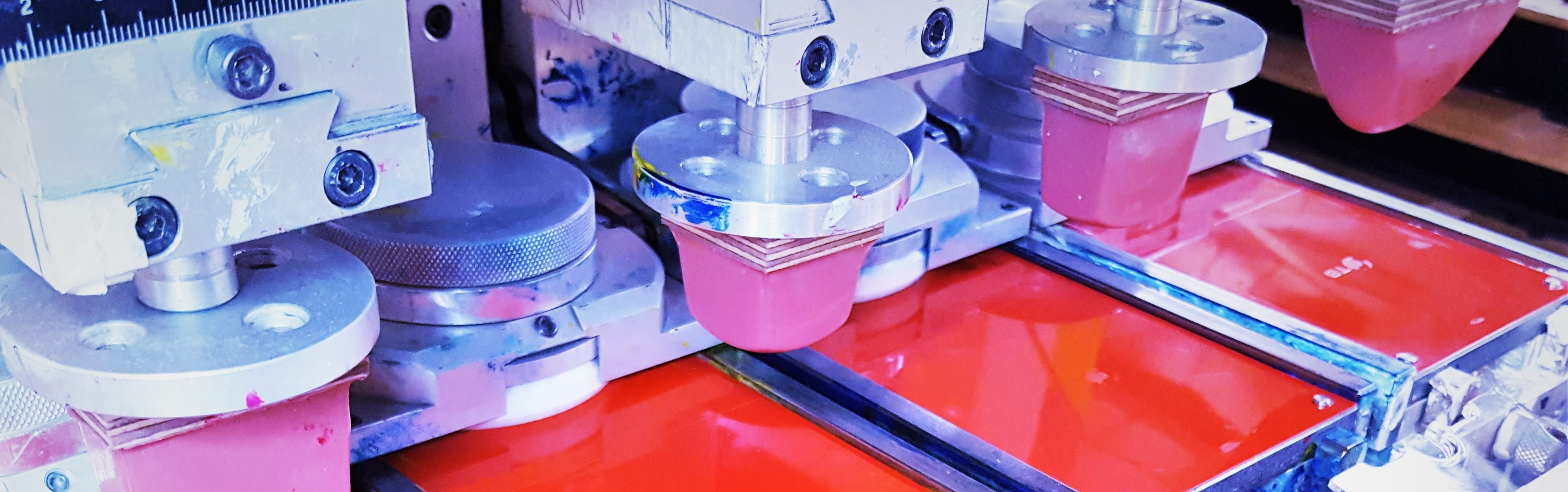

PAD PRINTING

-

Multi-station & multicolour facilities.

-

Typically combined with cosmetic spray painting for product enhancement.

PROTOTYPING

- RS Coatings can produce high quality prototypes with the use of 3D printing technology.

- Three dimensional CAD drawings presented as ”stl” files are loaded onto the machine to produce very accurate models achieving very tight tolerances with values down to 16 microns.

- Unlike stereolithographic prototypes, the models we manufacture are not fragile. These can be comfortably finished to the customers’ specifications to illustrate the look and function of production items.

- In some instances when the volumes required are low the 3D printed models can actually be used as functional products.

- We presently offer the option to manufacture models in two materials, white ABS or semintransparent acrylic.

LASER MARKING

-

Laser etching for function and brand recognition.

MANUAL & AUTOMATIC OPERATIONS

-

Manual and automated assembly operations are available offering a complete finishing service. Read More…

TECHNICAL SUPPORT

-

CAD.

-

Continued Technical Support is imparted from initial design to volume production.

VERSITILE MANUFACTURING

-

Production volumes to accommodate customers’ requirements.

-

Rapid response, efficiency & personalised service.

-

RS Coatings’ company portfolio includes renowned Electronics, Telecommunications, Instrumentation, Automotive and Merchandise Displays firms.